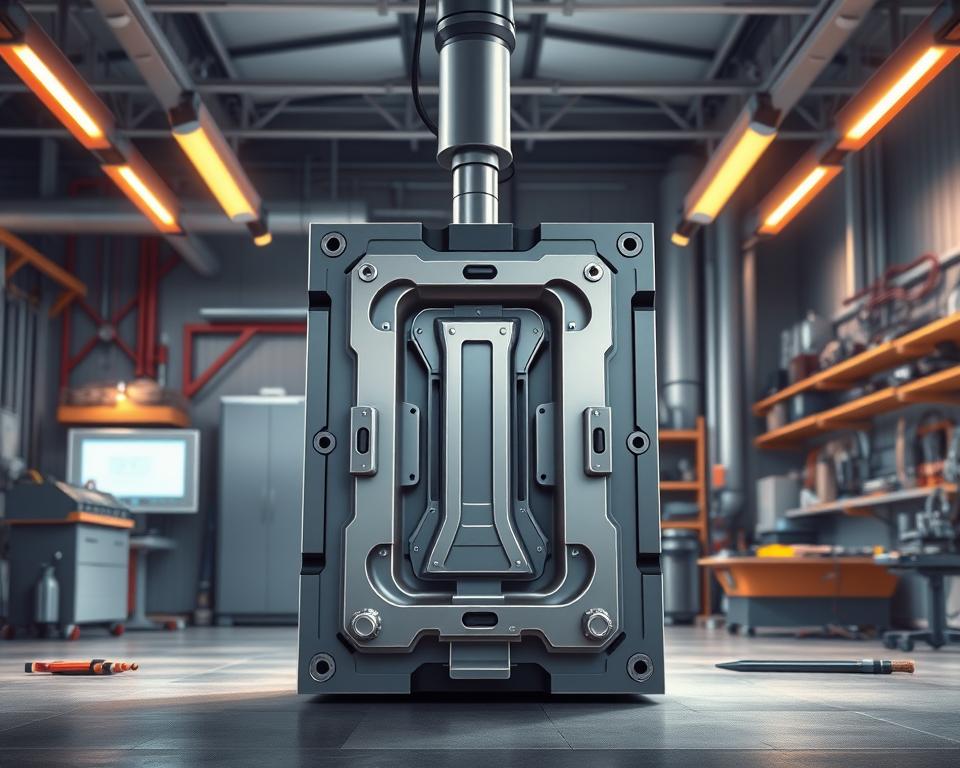

Expert Mold Design Solutions in Houston

The global injection molded plastics market is set to hit $440 billion by 2025. This growth underlines the importance of professional mold design services. They develop precision mold designs tailored to varied industries. Houston’s Lowrance Machine stands out as a premier mold design firm. They provide cutting-edge mold solutions for the automotive, aerospace, and consumer-goods markets.

With CAD and 3D-printing at its core, Lowrance Machine. Their experts guarantee both accuracy and speed throughout molding. Their seasoned experience and engineering prowess make them a dependable collaborator. Discover how their industrial molds Houston offerings improve project outcomes and satisfy current market needs.

Understanding the Importance of Mold Design Services

Quality and efficiency in manufacturing hinge on expert mold design services. Mold design dictates product performance and durability. By prioritizing professional mold design, firms reduce costs and improve quality measures.

Seasoned professionals at Lowrance Machine illustrate the benefits of expertise. They dive deep into client needs and work hand-in-hand to craft custom solutions. Through CAD-driven 3D modeling, they produce molds of exceptional standard.

Opting for premier mold design services elevates product functionality and powers business growth. Effective mold design leads to efficient manufacturing, giving companies a competitive edge in the market.

Available Mold Design Services in Houston

At Lowrance Machine in Houston, you’ll find varied mold design solutions designed for every industry. Knowing the different types of mold services helps businesses choose the best for their projects. Key categories include:

- Custom Design Solutions: Personalized mold design services built around specific demands.

- Test Mold Creation: Creation of prototype injection molds to test product designs before mass production.

- Injection Mold Fabrication: High-quality injection molds designed for durability and precision, ideal for various manufacturing applications.

- Advanced 3D Design: 3D-model-driven design for superior precision.

- Maintenance Services: Services aimed at extending the lifespan of existing molds through essential repairs and maintenance.

These services collectively enhance throughput, raise quality, and cut expenses. Knowing the service spectrum lets companies tailor mold design to their operational objectives.

Why Hire Professional Mold Designers

Engaging professional mold design teams offers significant process improvements. Expect greater precision, longer tool life, and faster cycles. Tailored molds ensure top-notch quality and repeatable outcomes.

Veteran designers inject invaluable process optimizations. They certify molds comply with both generic and custom criteria. Working together drives creative solutions and lengthens product durability.

Economical operations are a key perk. Advanced technology and methodologies reduce wastage and minimize delays. This results in substantial savings, boosting a manufacturing operation’s financial health. Swift design workflows speed time-to-market, sharpening competitive positioning.

In summary, specialized mold design companies provide critical support for manufacturers. They aim to optimize production capabilities and enhance product offerings.

Next-Gen Mold Design Innovations

Innovation has driven monumental shifts in mold design. At the forefront, Lowrance Machine applies state-of-the-art methods. These innovations boost productivity and improve product quality. Advanced mold design technologies play a significant role, streamlining the creation of unique molds and cutting down on time and costs.

3D-print-driven prototyping excels at rapid, complex mold creation. It significantly reduces material waste compared to traditional methods. Virtual simulation tools let engineers validate and optimize molds digitally for better accuracy and speed.

In Houston, mold design experts are embracing these modern strategies. Firms achieve market edge through digital design and high-tech manufacturing. They facilitate flexible, rapid-response mold development to satisfy diverse applications.

| Technique | Description | Benefits |

|---|---|---|

| 3D Printing | Utilizes additive manufacturing to create molds rapidly. | Shortens delivery times and cuts scrap. |

| Simulation Software | Offers virtual mold performance simulations. | Enhances accuracy and optimizes performance. |

| CAD Platforms | Utilizes CAD/CAM for exact design work. | Enables tailored designs and quick edits. |

Wrapping It Up

Professional mold design underpins both efficient operations and quality products in Houston. They provide the technical skill needed for complex mold projects. They tailor solutions to individual requirements for optimal results.

As a leader in accuracy and client partnership, Lowrance Machine stands out. Bespoke molds and innovative methods from professionals maintain market leadership. Working with mold design experts improves product quality and streamlines operations.

Investing in professional mold design in Houston focuses on quality and efficiency. Companies will satisfy market demands and sharpen their competitive edge. Adopting these specialized services is vital for manufacturers aiming to succeed in today’s competitive environment.